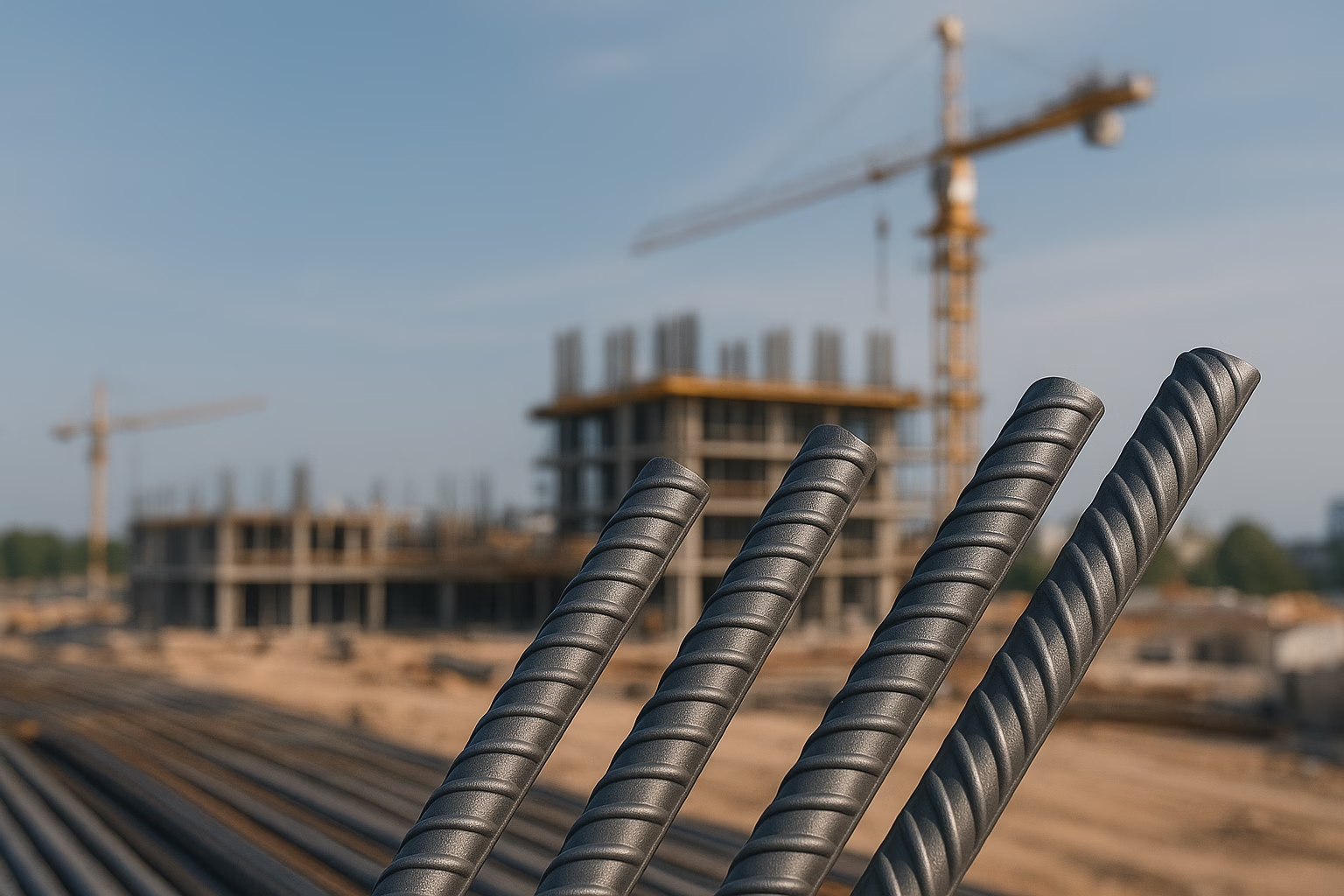

Selecting the right reinforcement steel is essential for the strength and longevity of any structure. TMT (Thermo-Mechanically Treated) steel bars are known for their robust outer surface and ductile core. Yet, with a multitude of grades and manufacturers available, determining the best TMT steel for your project can be overwhelming. This guide from RDTMT breaks down the process into clear sections to help you choose confidently.

TMT steel undergoes a specialized treatment where the hot steel bar is rapidly cooled on the outside and then tempering occurs from the remaining heat in the core. This results in a combination of high surface hardness and a flexible interior.

Look at the yield strength and ultimate tensile strength, measured in MPa, to ensure the steel can withstand expected loads and stresses.

Consider the alloying elements and any protective finishes that guard against rust, especially in humid or coastal environments.

Adequate deformation capacity without cracking is vital in seismic zones and during dynamic loading.

Balance the initial purchase price with long-term maintenance, transportation, and installation costs to find the optimal value.

BIS Certification ensures compliance with national standards (IS 1786:2008) for strength and durability.

ISO Standards (ISO 9001 for quality management, ISO 14001 for environmental processes, ISO 45001 for safety) demonstrate commitment to best practices.

Testing Methods include tensile strength, yield point, elongation, and bend tests to verify performance under real-world conditions.

Recyclability of TMT steel reduces landfill waste and conserves resources.

Energy Efficiency in modern mills uses heat recovery and optimized cooling to lower power consumption.

Carbon Footprint is mitigated by cleaner production technologies and renewable energy adoption.

By understanding TMT steel grades, evaluating critical performance factors, and comparing leading brands, you can select the most suitable TMT steel for your project’s unique demands. Trust RDTMT to deliver the quality and reliability your construction deserves.