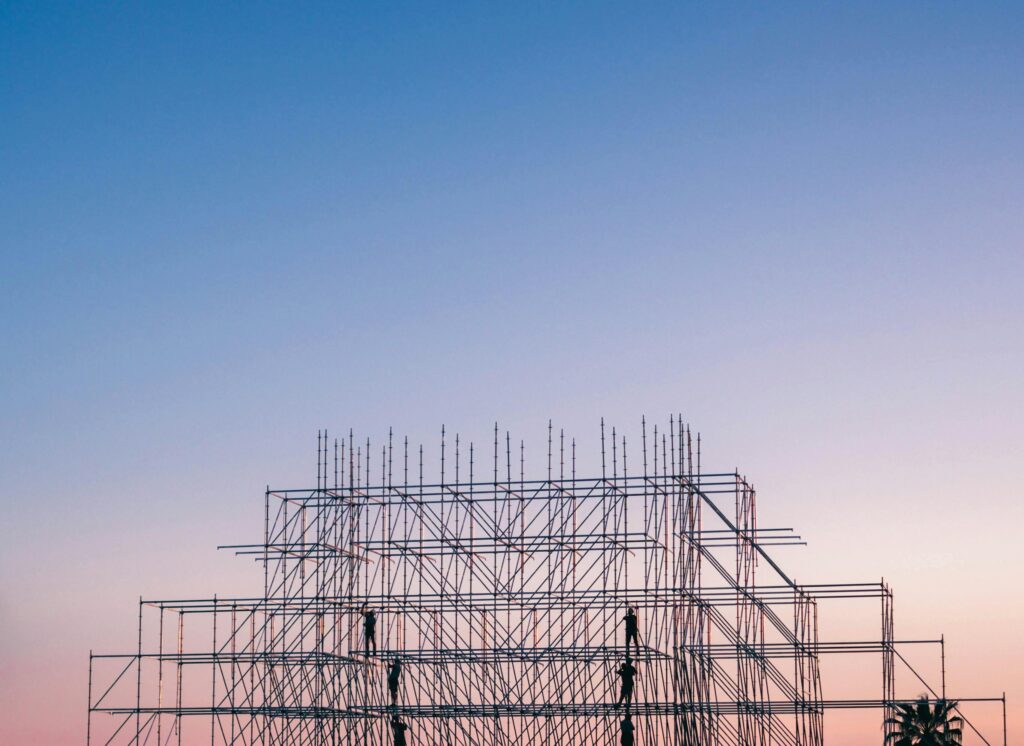

Concrete is one of the most widely used construction materials, prized for its durability and strength. However, even the strongest concrete structures can develop cracks over time, compromising their structural integrity and aesthetics. Understanding the common causes of cracks in concrete is crucial to addressing this issue and ensuring the longevity of buildings and infrastructure.

Cracks in concrete can arise from various factors, including shrinkage, temperature changes, settlement, and overloading. These cracks not only detract from the appearance of a structure but can also pose serious safety risks if left unchecked. Identifying and mitigating the root causes of cracking is essential for maintaining the integrity and functionality of concrete structures.

One potential solution to combat cracking in concrete is the use of Thermo-Mechanically Treated (TMT) reinforcement bars. These specialized bars undergo a unique manufacturing process that enhances their strength, ductility, and corrosion resistance, making them an attractive option for reinforcing concrete structures. By understanding the causes of cracks and exploring the benefits of TMT bars, we can take proactive steps to ensure the durability and safety of concrete constructions.

Concrete is sensitive to temperature fluctuations. When exposed to extreme heat or cold, concrete will expand or contract. This expansion and contraction can create thermal stresses within the material, leading to cracking. Rapid temperature changes can be particularly problematic, as the surface of the concrete may expand or contract more quickly than the interior, resulting in surface cracking.

Over time, the ground or surface beneath a concrete structure can settle or shift. This can cause differential movement, where different parts of the structure move at different rates. Such movements create tensile stresses within the concrete, which can lead to cracking. Factors that can contribute to settlement include changes in soil moisture, erosion, and even the weight of the structure itself.

Concrete structures are designed to withstand specific loads. If a structure is subjected to loads that exceed its design capacity, it can cause excessive stress within the concrete, resulting in cracking. Overloading can occur due to various factors, such as adding additional floors to a building, changes in the intended use of the structure, or natural disasters like earthquakes or hurricanes.

TMT (Thermo-Mechanically Treated) bars are an excellent solution to mitigate the effects of cracks in concrete structures. These bars offer several benefits that contribute to the overall strength, durability, and longevity of concrete constructions.

TMT bars undergo a specialized heat treatment process that enhances their resistance to corrosion. This heat treatment involves carefully controlling the temperature and cooling rate of the steel, which results in a more uniform and durable microstructure. The improved corrosion resistance of TMT bars is a significant advantage as it helps prevent the expansion of concrete due to the corrosion of the reinforcing steel.

When steel reinforcement corrodes, it can cause the formation of rust, which occupies a larger volume than the original steel. This expansion can exert tremendous internal pressure on the surrounding concrete, leading to cracking and spalling. By using TMT bars with superior corrosion resistance, the risk of this type of concrete deterioration is significantly reduced, thereby extending the service life of the structure and minimizing the likelihood of cracks forming due to corrosion-related expansion.

TMT bars offer superior strength and durability, making concrete structures more resilient against cracks caused by overloading or excessive stress. These bars are designed to withstand heavy loads, reducing the risk of cracks forming due to structural overload. With their enhanced tensile strength, TMT bars reinforce the concrete matrix, enabling it to bear greater loads without compromising integrity.

The use of TMT bars in concrete construction significantly reduces the likelihood of cracks developing due to overloading. Their high strength-to-weight ratio ensures that the structure can withstand substantial loads while maintaining its structural integrity. This minimizes the risk of cracks forming, which can compromise the overall durability and safety of the building.

Moreover, TMT bars contribute to the enhanced durability and longevity of concrete structures. Their superior corrosion resistance and ability to withstand harsh environmental conditions help extend the lifespan of the structure. By mitigating the effects of corrosion and other deteriorating factors, TMT bars ensure that the concrete remains intact and free from cracks, even after years of exposure to various elements.

In areas prone to earthquakes and seismic activity, TMT bars offer a crucial advantage by providing enhanced ductility to concrete structures. Ductility refers to the ability of a material to deform plastically without fracturing or failing catastrophically. This property is particularly important in earthquake-resistant design, as it allows structures to bend and flex under seismic loads, dissipating energy and preventing sudden, brittle failures.

TMT bars possess superior ductility compared to conventional reinforcement bars, thanks to their unique manufacturing process involving quenching and tempering. This heat treatment improves the steel’s ability to undergo significant deformation without losing its load-bearing capacity. As a result, structures reinforced with TMT bars can withstand the intense shaking and lateral forces generated during earthquakes, bending elastically instead of breaking abruptly.

During a seismic event, the ground motion can cause structures to oscillate and sway, subjecting them to substantial lateral loads. TMT bars, with their enhanced ductility, can accommodate these movements without fracturing, allowing the structure to deform and absorb energy without catastrophic failure. This ductile behavior helps prevent the sudden collapse of buildings, providing valuable time for occupants to evacuate safely.

Moreover, the ductility of TMT bars contributes to the overall resilience of the structure, reducing the risk of progressive collapse. Even if localized damage occurs, the ductile reinforcement can redistribute forces and maintain structural integrity, preventing a cascading failure throughout the entire building.

TMT bars exhibit exceptional fatigue resistance properties, making them an ideal choice for applications where structures are subjected to repeated stress cycles or dynamic loading. This characteristic allows the bars to withstand numerous cycles of loading and unloading without compromising their structural integrity.

Fatigue cracks are a common issue in concrete structures that experience cyclic loading, such as bridges, offshore platforms, and machinery foundations. These cracks can propagate over time, leading to potential failures. TMT bars, with their superior fatigue resistance, help prevent the formation and propagation of fatigue cracks, ensuring the longevity and safety of the structure.

The ability of TMT bars to withstand repeated stress cycles is particularly beneficial in structures exposed to dynamic loads, such as those caused by wind, wave action, or seismic activity. By incorporating TMT bars into the design, these structures can better withstand the cyclical stresses without experiencing premature cracking or failure, thereby enhancing their overall durability and service life.

Cracks in concrete structures can arise from various factors, including shrinkage, temperature changes, settlement, and overloading. These cracks not only compromise the aesthetic appeal but also pose a significant threat to the structural integrity and safety of buildings. Fortunately, the use of TMT bars can effectively mitigate the occurrence and severity of cracks, ensuring the longevity and durability of concrete structures.

The key advantages of TMT bars lie in their superior corrosion resistance, increased strength and durability, enhanced seismic resistance, and exceptional fatigue resistance properties. By incorporating TMT bars into concrete structures, builders and engineers can significantly reduce the risk of cracking caused by various environmental and mechanical factors.

However, it is crucial to note that the effectiveness of TMT bars in preventing cracks is maximized when combined with proper design principles, high-quality materials, and regular maintenance practices. A comprehensive approach that considers all aspects of construction is essential for achieving optimal results.

For those seeking reliable and high-performance TMT bars, RDTMT TMT bars are an excellent choice. Engineered with the latest technology and designed to withstand maximum stress and pressure, RDTMT TMT bars offer unparalleled strength and durability, ensuring the safety and security of your projects for years to come.